Losing Resources to Spoilage and Waste? Here’s a Smarter Way to Store Bulk Materials with Fabric

Why Are Municipal and Commercial Sites Losing Product?

When salt, sand, or other stockpiled materials are left exposed to the elements, it’s common to experience loss. Moisture can reduce handling efficiency, and extreme weather can impact the condition of your stored product. Over time, this leads to material shrinkage, handling issues, and operational slowdowns.

What Causes Spoilage in Bulk Material Storage?

Rain, wind, and snow can compromise unprotected storage areas. Rainwater can break down piles of salt or soak through compost and sand, increasing moisture content. This adds weight, creates handling delays, and can reduce the condition of the material when you need it most.

How Can a Fabric Building Help?

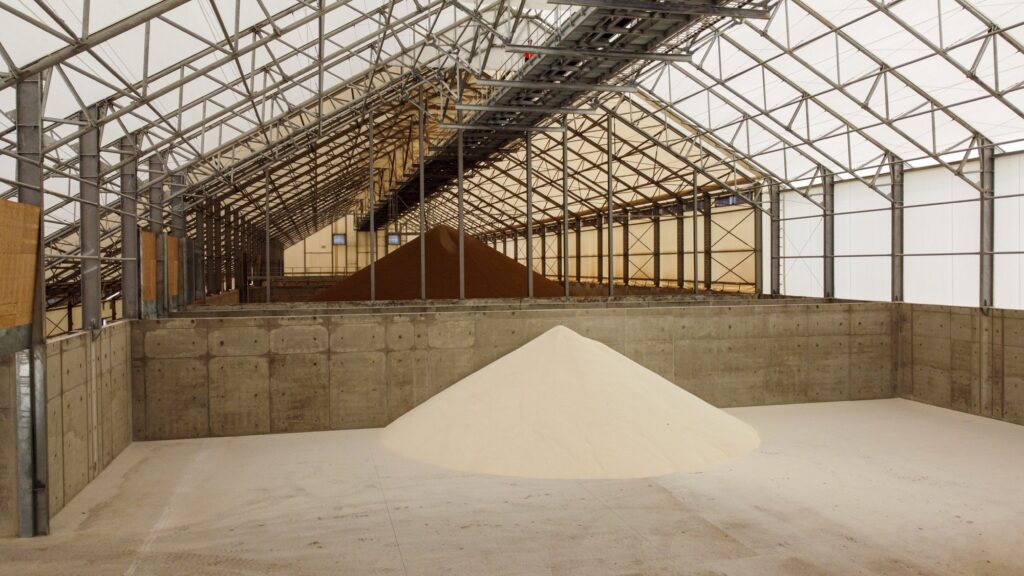

A fabric-covered storage building creates a protected environment that helps reduce weather impact. These engineered structures are used for salt domes, municipal sand storage, and other public works material sheds. The design helps keep bulk material dry and accessible while supporting daily equipment access.

Designed for Bulk Storage Efficiency

Britespan buildings are clear-span, meaning there are no interior posts to interfere with equipment. This design is preferred for sites that require:

- Frequent in-and-out traffic

- On-site loaders or conveyors

- Maximized use of interior space

Additional features include:

- High-clearance interiors for vertical stacking

- Flexible entry options including roll-up doors or curtains

- Compatibility with bins, ramps, and bulk delivery systems

What Are the Operational Advantages?

A dry, well-contained stockpile is easier to manage. Users often report:

- Shorter equipment cycles

- Less material tracking or slippage near the work zone

- Fewer delays during load-in or load-out

- Easier cleanup during seasonal changeovers

These advantages can help crews stay on task with fewer interruptions.

Are Fabric Buildings Permanent?

Yes. Britespan structures are engineered for long-term use. They’re built with galvanized steel trusses and tensioned fabric designed to handle snow, wind, and continuous operation. Each structure is engineered to meet your site’s local building codes.

These buildings are also modular, which means layouts can be customized to suit your footprint or adapted over time.

Case Use Examples

Britespan fabric buildings have been used by public works departments, contractors, and municipalities to store:

- Road salt and deicing agents

- Sand and soil for grading and backfill

- Recycling or transfer station materials

- Compost and dry yard waste

These buildings are often placed on concrete pads or gravel bases and can be anchored using pier or block foundations, depending on your site needs.

Common Questions

What is the best type of building for storing salt or sand?

Fabric-covered buildings are often used for municipal salt and sand storage because they offer full weather protection, quick installation, and open-span interiors for equipment movement.

Can I use a fabric building in a public works yard?

Yes. Britespan buildings are designed for municipal use and can be sized and configured for salt domes, material bays, or general yard storage.

How long do these buildings last?

When maintained properly, fabric buildings can perform for decades. The galvanized steel frames resist corrosion, and the fabric cover is designed to handle seasonal exposure.

Do I need a concrete foundation?

Not always. Many installations use piers, concrete blocks, or gravel foundations depending on the size and use of the structure.

Can I get a custom layout?

Yes. You can choose building width, sidewall height, door placement, and ventilation options to meet your workflow and access needs.

Start Planning a Better Storage Solution

Britespan works with each customer to design a structure that fits the space, workflow, and material handling requirements of your operation. Whether you’re upgrading your salt shed or planning a new waste management facility, our team can help you explore layouts and construction timelines.

Reach out today to explore your options. We’ll guide you through sizing, configuration, and installation planning based on your site conditions and goals. No pressure, just practical answers from a team experienced in bulk material storage.