The Value of Custom Engineered Fabric Structures for Your Unique Project

Every site is different, and every operation has its own workflow. That is why custom-engineered fabric structures deliver more value than one-size-fits-all kits. When the frame, openings, clearances, and accessories are designed around your tasks and climate, the building works like part of your process. The result is better safety, higher productivity, and a longer service life than templated solutions.

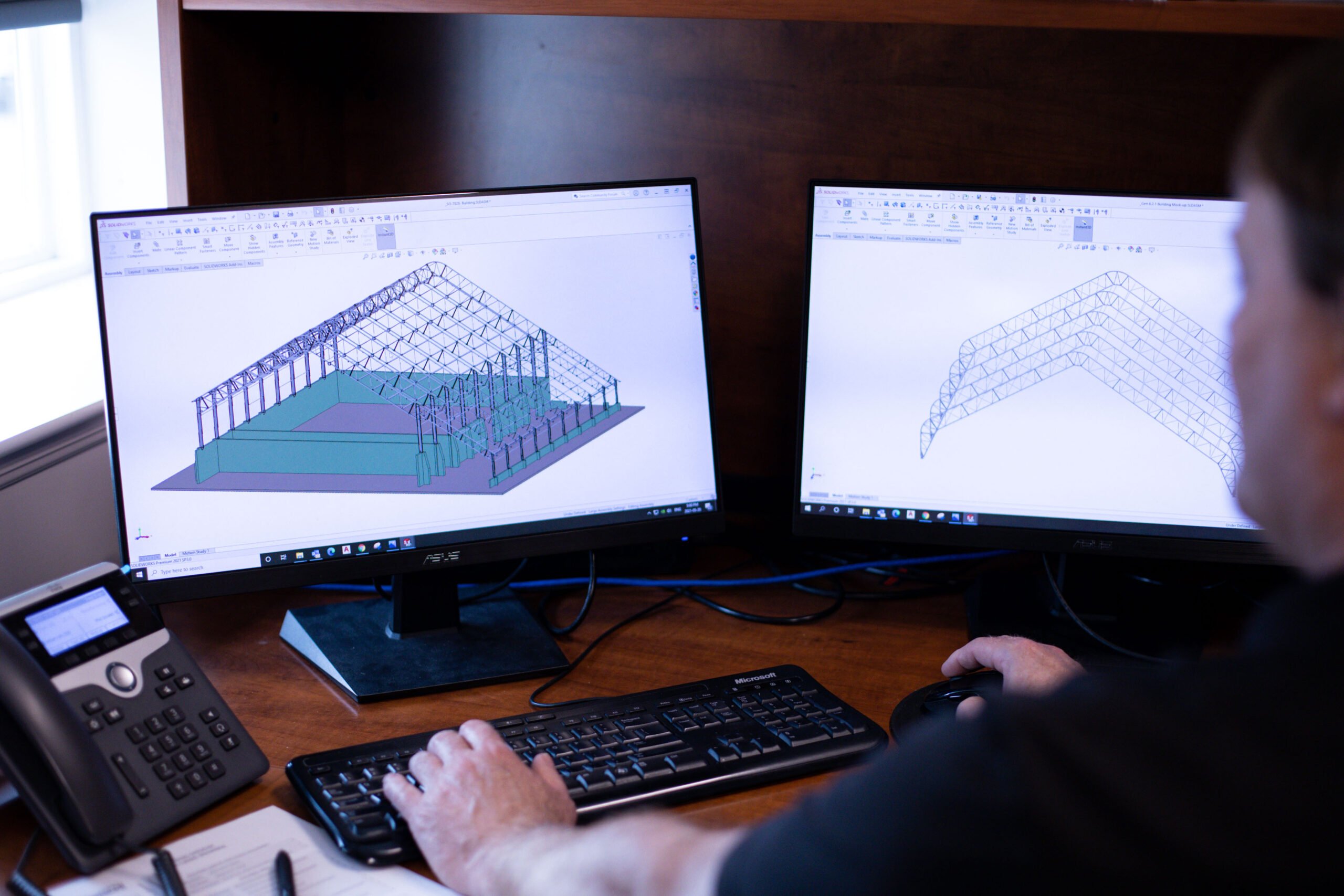

What Makes an Engineered Fabric Structure Truly Custom

A true fabric building custom design starts with your constraints and goals, not a preset kit. Width, length, peak height, eave height, and truss spacing are sized for your equipment and traffic patterns. Sidewall clearance, roof pitch, and door placement are set so loaders, tandems, or feed trucks move without bottlenecks. That is a custom design for fabric buildings in practice.

Beyond geometry, engineered fabric building specifications match your site conditions. Snow loads, wind zones, exposure categories, and occupancy drive the steel selection and connection details. Ventilation, natural daylighting, and electrical systems are planned together, so air exchange and visibility support the work you do. The difference is easy to feel on day one. Doors align with real routes. Clear spans eliminate unnecessary posts. The building fits like a tool you chose for the job.

How Custom Engineering Fabric Structures Improve Efficiency, Safety, and Longevity

A building that adapts to your workflow saves time every shift. Clear spans let operators turn and stage where it makes sense. Door packages sized to the largest unit prevent delays. Vent paths that pull moisture and fumes up and out keep interiors drier and easier to inspect. These are core custom fabric structure benefits that compound across seasons.

Safety improves when the design respects both code and reality. Proper egress, lighting levels that reduce shadows, and airflow that limits condensation help crews see and move with confidence. Structural choices matter as well. Hot dip galvanized frames, sealed hardware in splash zones, and appropriate foundations reduce corrosion and keep frames true. A building that stays square keeps doors tracking and fabric tensioned, which protects the cover and reduces maintenance.

Longevity comes from aligning design with the environment. Coastal yards, fertilizer sheds, or salt storage benefit from corrosion conscious packages, while high-UV regions prioritize fabric choices with strong UV stability. When details match the exposure, repairs drop and useful life rises. That is the quiet value of custom fabric structures over time.

Our team diligently prepares specialized fabric components, a crucial step in the custom engineering of high-quality fabric structures for diverse applications.

Why Templates Fall Short For Complex Sites

Pre engineered fabric structures sold strictly as kits can be quick to order, but they often force compromises. Fixed widths or door positions may not fit tall equipment, wide attachments, or required traffic flows. Limited sidewall height can crowd the edges where you actually work. Generic ventilation or lighting layouts can miss moisture sources and blind corners.

By contrast, custom engineered fabric structures preserve speed while solving the specifics. You still get pre-engineered components and rapid installation, but the spec is yours. If you need a mixed bay with one extra-tall door, or a longer eave for covered load-out, or a ridge configuration that favors natural draft, custom engineering makes it straightforward. Even when you choose pre engineered fabric structures as a delivery method, the design can remain project-specific.

Use Cases Custom Engineered Fabric Structures.

Agriculture

Feed barns and equipment storage benefit from bright interiors and steady airflow. Pens, alleys, and feed lanes align with chores, not with arbitrary column grids. Sidewall clearance supports rations and bedding management. For storage, tall doors and open spans keep combines, headers, and sprayers moving without risk to panels or mirrors. Moisture control protects hay and feed quality.

Commercial and Industrial

Maintenance shops, logistics yards, and manufacturing need wide clearances, one-way traffic, and doors where trucks actually arrive. Crane loads, wash bays, or parts mezzanines can be designed in from the start. Corrosion packages suit salt, fertilizer, coastal air, or frequent washdowns. Lighting and ventilation plans support long shifts and reduce fatigue.

Municipal and Public Works

Salt and sand storage requires capacity, loader geometry, and compliance. Push walls, curbs, and apron drainage support containment and housekeeping. High-cycle doors, simple controls, and clean sightlines keep cycles short during storms. If you need surge space or phased expansions, modular length additions preserve continuity while you grow.

Key Decisions That Turn A Fabric Shell Into A High-Performing Facility

Geometry that matches the equipment

Confirm turning radii, door width and height, and staging areas. Set clear spans and eave heights to your largest unit with room to spare.

Foundations and anchorage that protect alignment

Choose slabs, curbs, piles, or ground screws based on soils and frost depth. The right base preserves plumb frames and fabric tension.

Ventilation that fits the use

Ridge vents, chimneys, sidewall inlets, or fan assists should match the heat, moisture, and fumes produced by your work.

Lighting that reduces shadows

Translucent fabric helps, but targeted task lighting at entries, intersections, and work zones keeps visibility crisp.

Corrosion resistance where it matters

Hot-dip galvanizing, sealed connections, and liners in high-impact areas extend life in corrosive environments.

Future proofing

Plan modular length additions, door relocations, and service stubs so the building scales as your operation grows.

Ready To Invest in Engineered Fabric structures?

If you are weighing a kit against a tailored approach, start with the basics. List your equipment, map turning paths, confirm local loads, and note your target in-service date. Share a simple sketch and a few site photos. From there, we can shape a plan with the right openings, ventilation, and foundations so the building fits your workflow on day one.

Ready to get started? Contact our team, and will turn your requirements into a clear, buildable design that improves safety, speeds daily work, and stands up over time.