Key Considerations for Building High-Functioning Aircraft Hangars

Britespan Aircraft hangars serve as both protectors and functional spaces for valuable aviation assets, including airplanes, helicopters, and related equipment. The process of designing and constructing an efficient and sustainable aircraft hangar necessitates planning and detailed attention to a multitude of elements. In this guide, we explore essential considerations for architects and engineers involved in aircraft hangar design and the hangar cost to build. This exploration includes the latest trends in aviation needs, the integration of cutting-edge materials, and the adaptation of designs to meet evolving aviation standards.

Budgeting for Success: An In-Depth Approach

You may wonder how much it costs to build an aircraft hangar? Managing the budget is a crucial facet in ensuring the fiscal success of any aircraft hangar project. This planning encompasses a wide array of costs, including those associated with materials, labor, potential site work, and other ancillary expenses, all while focusing on fabric structure elements. A critical aspect of this initial step is the consideration of various environmental and structural variables, such as the potential impact of snow load and wind rating on the hangar’s truss spacing, which can have significant implications on the project’s overall design and costs, particularly in terms of fabric structure elements.

A key decision in the cost to build an aircraft hangar is the selection of structural designs that balance cost-effectiveness with functional efficiency, with a focus on fabric structure elements. In this context, the use of a Tension Membrane Structure often emerges as the lowest cost per square foot. This structural option is typically about 30% less costly than traditional alternatives, coupled with a notably faster lead time, and is a prime example of an efficient fabric structure element. Such a cost-effective solution does not only ensure fiscal responsibility but also aligns with project timelines and efficiency goals. Additionally, the foundational aspects of the hangar construction, which typically account for about 10-25% of the total project cost, offer a spectrum of choices. These range from the sturdy and enduring concrete stem wall foundations to the innovative and adaptable Container Buildings. It is important to acknowledge that fluctuations in snow load and wind rating can influence truss spacing, necessitating consideration within the established cost ranges.

Delving deeper into the specifics of budget allocation, the costs associated with materials emerge as a critical component. Typically, these costs range from $10 to $20 per square foot, playing a decisive role in determining the project’s physical framework and overall aesthetic, with fabric structure elements being a key factor. Alongside material costs, labor expenses also hold a prominent position in the budgeting strategy. With labor costs varying between $4 and $10 per square foot, depending on the project’s location, complexity, and the skill level required, they form a substantial portion of the overall expenditure.

Understanding the Importance of Aircraft Hangar Size:

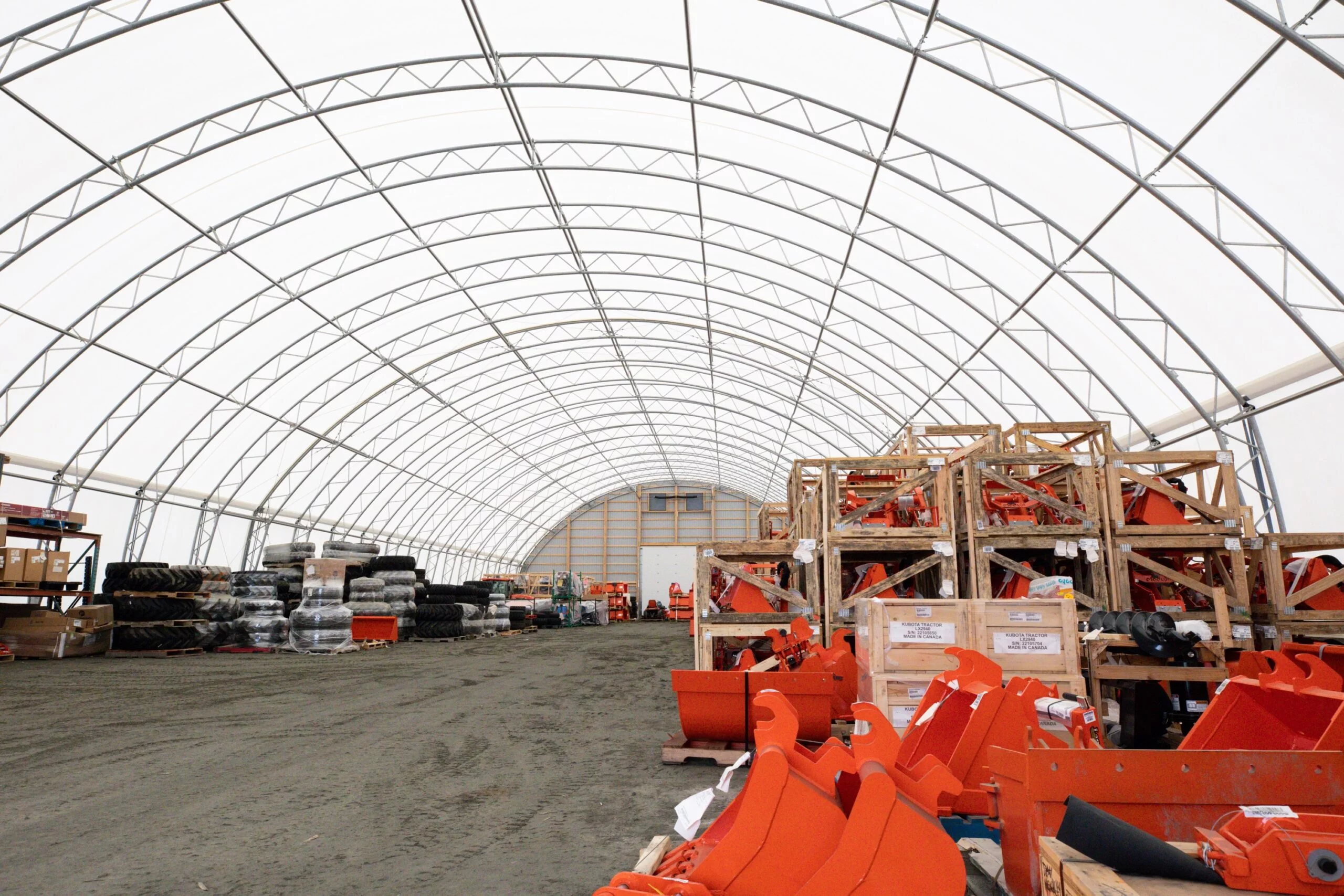

Choosing the appropriate size for an aircraft hangar is crucial for optimal functionality. It’s essential to take into account not just the dimensions of the aircraft itself but also the additional space required for smooth maneuvering, strategic placement of equipment, and effective maintenance operations. Aircraft fabric structures, which come in a variety of sizes with widths that can vary from a compact 30 feet to an expansive 250 feet, provide both flexibility in design and sufficient height clearance. This variety in size ensures that different types of aircraft can be accommodated comfortably. Moreover, the availability of diverse foundation options further broadens the possibilities for hangar placement, making it easier to tailor the hangar to specific site requirements and environmental conditions. This adaptability is key in ensuring that the hangar not only houses the aircraft but also supports all associated activities efficiently, with fabric structure elements playing a significant role in the overall aircraft hangar design.

Electrical Blueprint for Aircraft Hangars:

The careful and detailed planning of electrical needs is fundamental to the functionality of an aircraft hangar. It is vital to ensure that there are enough power outlets, which should be strategically positioned throughout the hangar to facilitate easy access during servicing and maintenance activities. These outlets should be placed in locations that optimize efficiency and safety for technicians and engineers working in the hangar. In hangars that cater to larger aircraft or have more intensive electrical requirements, it may be necessary to design the building with an increased collateral load capacity. This is particularly important when considering systems such as fire suppression, which can have significant electrical demands. Ensuring that the hangar is equipped to handle these demands is crucial for both the operational efficiency of the hangar and the safety of the aircraft and personnel within, with fabric structure elements being a key factor in the overall hangar design.

Door Designs for Enhanced Accessibility in Hangars:

The design and functionality of entry and exit points are integral to the overall efficiency of a hangar. It’s important to choose door options that align with the hangar’s design and its intended use. There are several types of doors available, each offering unique advantages. For instance, bi-folding doors, vertical lift doors, and sliding doors are popular choices. Sliding doors are frequently chosen for their cost-effectiveness, making them a practical option for budget-conscious projects. On the other hand, vertical lift and bi-folding doors are known for their ability to maximize space utilization within the hangar. This is particularly beneficial in hangars where space conservation is a priority. Ensuring that the doors are of the right size is also crucial. Properly sized doors significantly enhance accessibility, which is a key factor for the smooth movement of aircraft in and out of the hangar. This aspect of hangar design is essential for maintaining a seamless flow of operations and ensuring the hangar serves its purpose effectively, with fabric structure elements being a crucial component in the overall design.

Solid Foundations: Hangar Flooring

Considering the substantial weight and challenging environmental factors, the foundations of aircraft hangars require extra focus and robust construction. The use of reinforced concrete in the foundations offers the necessary stability and strength to support heavy aircraft. In addition, the flooring, typically made of solid aggregate concrete, is designed to endure significant pressure and stress, ensuring a long-lasting and resilient surface. To further enhance the flooring’s functionality, a durable epoxy coating is applied. This coating not only provides resistance against various chemicals, which is crucial in a hangar environment, but also improves traction. This is particularly important for the safe and efficient movement of aircraft within the hangar, as it minimizes the risk of slips and skids. Overall, these elements combine to create a hangar flooring system that is both sturdy and safe, catering to the demanding needs of aircraft storage and maintenance, with fabric structure elements being a key factor in the overall design.

Illuminating the Space: Hangar Lighting

The expansive nature of an aircraft hangar design demands meticulous planning in terms of lighting. Crafting a strategic lighting design is essential, and incorporating elements like skylights can significantly enhance natural illumination within the space. This approach not only creates a workspace that is well-lit and conducive to productivity but also taps into the benefits of natural light. The use of a Polyethylene fabric cover, which is characteristically translucent, plays a pivotal role in this design. Its ability to allow sunlight to filter through effectively reduces the reliance on artificial lighting sources and could give a large boost in productivity during aircraft maintenance and repair. This not only helps in creating a more naturally bright environment but also contributes positively to eco-friendly design principles. By minimizing the need for artificial light, the hangar becomes more energy-efficient and aligns with sustainable design goals, making it an environmentally conscious choice, with fabric structure elements being a central aspect of the lighting design.

The construction of an efficient and effective aircraft hangar is a complex process that requires a harmonious blend of various factors. These include careful budget management, precise sizing and dimension planning, detailed electrical layout considerations, and the incorporation of sustainable design elements. The role of architects and engineering experts is crucial in this process. They are responsible for designing hangars that fulfill operational requirements while prioritizing the safety and security of the aircraft housed within. Their expertise ensures that the hangar not only functions efficiently but also adheres to the highest safety standards. Furthermore, collaboration with seasoned industry professionals is essential in navigating the intricacies of such large-scale projects. Adherence to regulatory compliance standards is another critical aspect, ensuring that the hangar meets all legal and safety requirements. At Britespan we are always going to design the building to your specific site location to meet these requirements. This comprehensive approach is key to the successful development and implementation of large-scale aircraft hangar projects, ensuring they meet the highest standards of functionality, safety, and efficiency, with fabric structure elements being an excellent choice in the overall design.